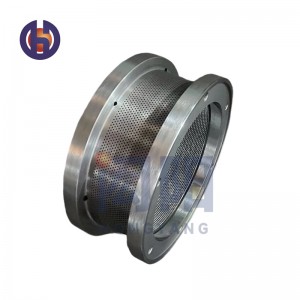

Nplhaib Tuag Awila420 Pellet Tuag Awila 420

Cov ntaub ntawv khoom

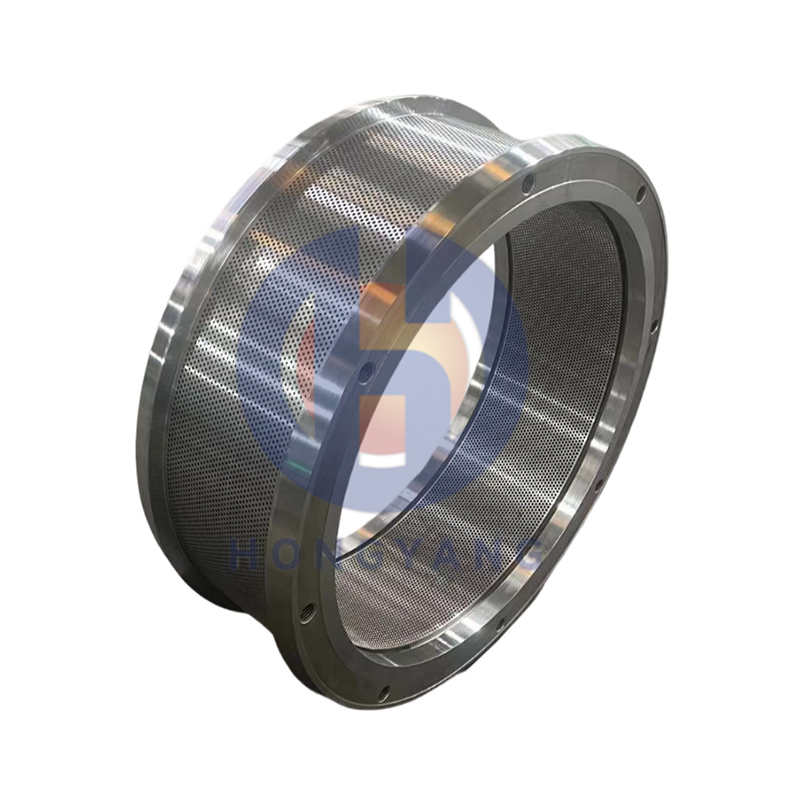

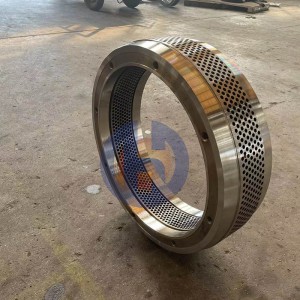

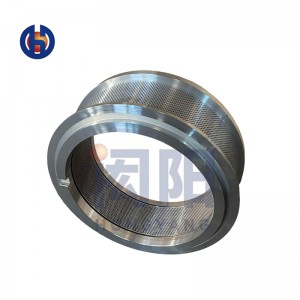

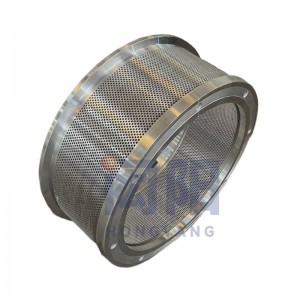

Pellet mills yog cov tshuab siv los ua cov ntaub ntawv raw rau hauv pellets. Cov pellets no yog cov khoom siv hluav taws xob zoo thiab feem ntau siv hauv cov tshuab cua sov thiab cov chaw tsim hluav taws xob. Lub nplhaib tuag yog ib qho tseem ceeb ntawm lub tshuab pellet, lub luag haujlwm rau shaping cov ntaub ntawv raw rau hauv pellets.

Kev tsim ntawm lub nplhaib tuag ncaj qha cuam tshuam rau cov txiaj ntsig thiab qhov zoo ntawm cov pellets tsim. Cov qauv kev hla thiab qhov ntev ntawm lub nplhaib tuag tsim yog qhov tseem ceeb hauv kev txiav txim siab qhov loj me thiab cov duab. Nrog rau qhov tseeb dhau tus qauv, cov neeg siv tuaj yeem tsim cov pellets ntawm ntau qhov sib txawv thiab cov duab raws li lawv xav tau. Yog li ntawd, nws yog ib qho tseem ceeb los xyuas kom meej tias koj tau txais ib lub nplhaib tuag nrog ib tug pass qauv optimized rau hom pellets koj ua.

Nrog rau txoj cai nplhaib tuag, cov neeg siv tuaj yeem ua tiav cov pellet ceev dua, uas txhais tau tias ntau cov pellets tuaj yeem ntim rau hauv qhov chaw cia. Tsis tas li ntawd, denser thiab smoother pellets siv tsawg zog thaum nws los txog rau kev thauj mus los, uas ua rau txo nqi tsheb thauj mus los. Nrog rau qhov no, koj cov pellets yuav muaj kev puas tsuaj tsawg dua thiab tawg thaum lub sijhawm thauj mus los, kom ntseeg tau tias koj tau them rau txhua lub hnab xa khoom.

Pob khoom

1. Feem ntau, lub nplhaib tuag yuav raug qhwv zoo hauv cov yeeb yaj kiab yas tsis muaj dej.

2. Lub nplhaib tuag yog muab tso rau hauv rooj plaub ntoo lossis tsau rau ntawm cov pallets (raws li cov neeg siv khoom thov), thiab tom qab ntawd muab tso rau hauv cov thawv.

3. Txheem exporting pob, muaj kev nyab xeeb thiab ruaj khov, uas yog tsim rau kev thauj mus los ntev.

Khoom Qhia

Peb tuaj yeem muab ntau hom nplhaib tuag. Peb tuaj yeem kho qhov loj thiab cov duab rau koj raws li koj daim duab.