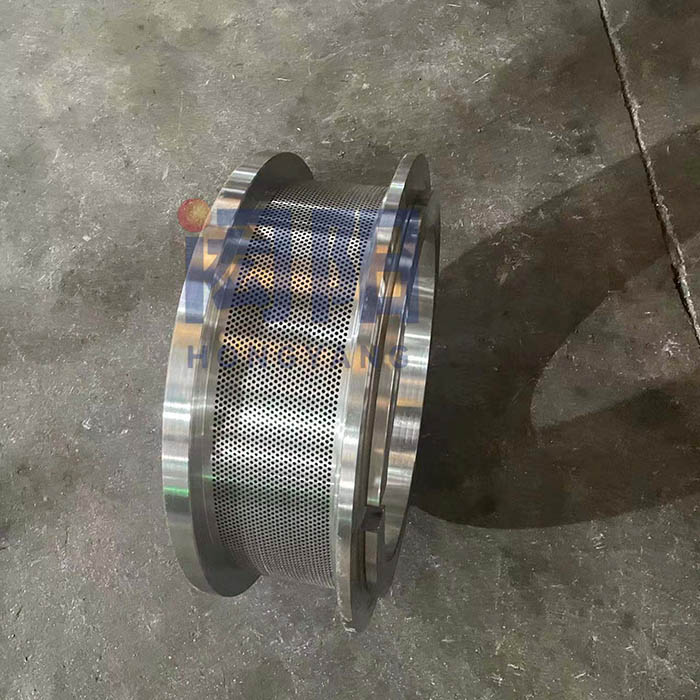

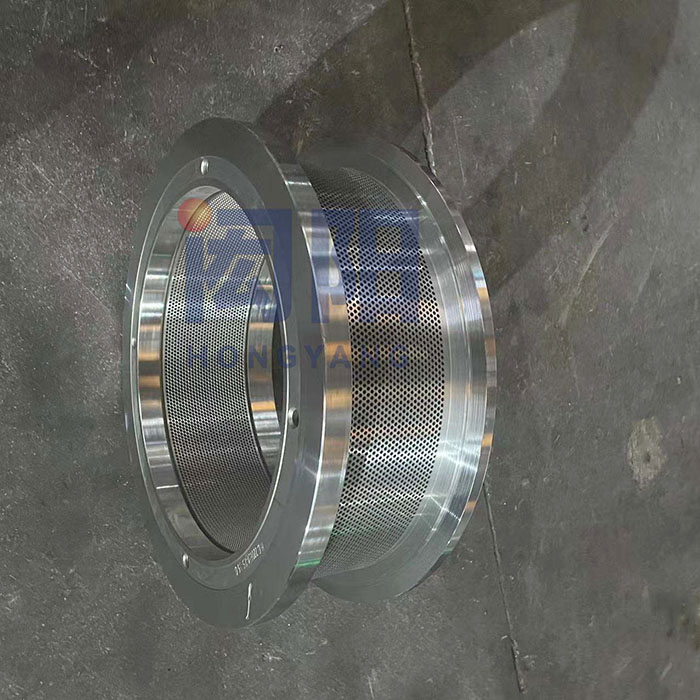

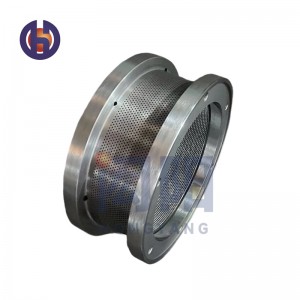

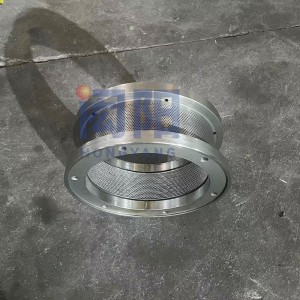

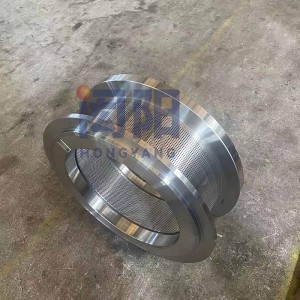

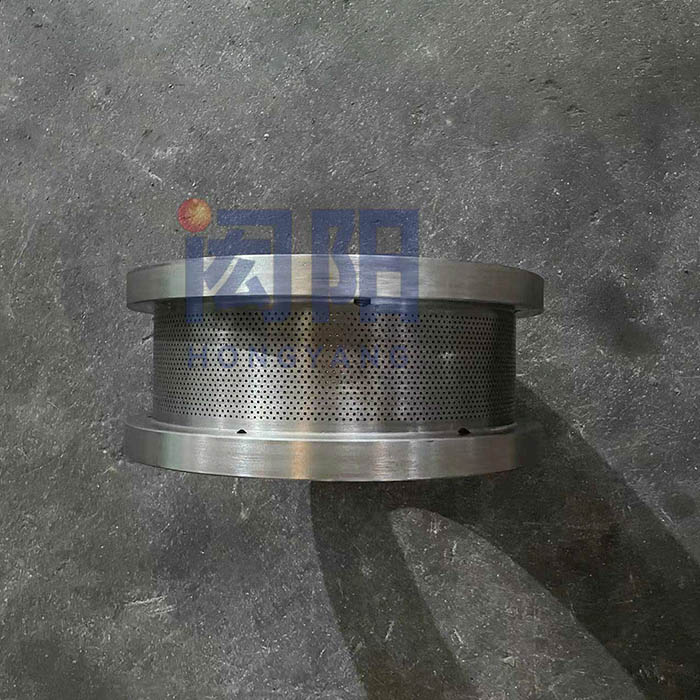

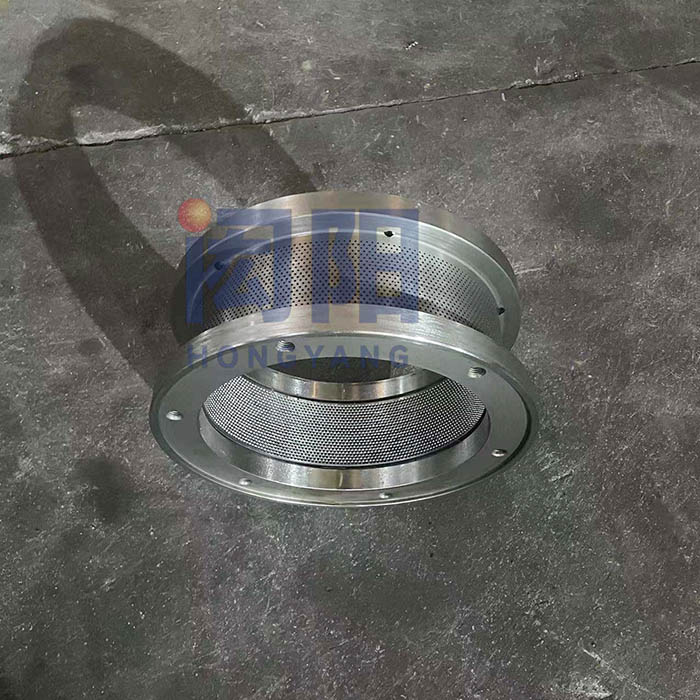

Feed Pellet Ring Tuag HUAMU HKJ 250

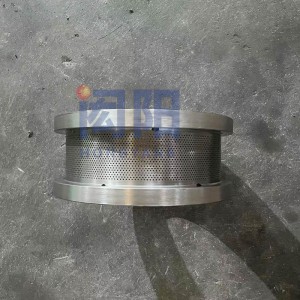

Khoom nta

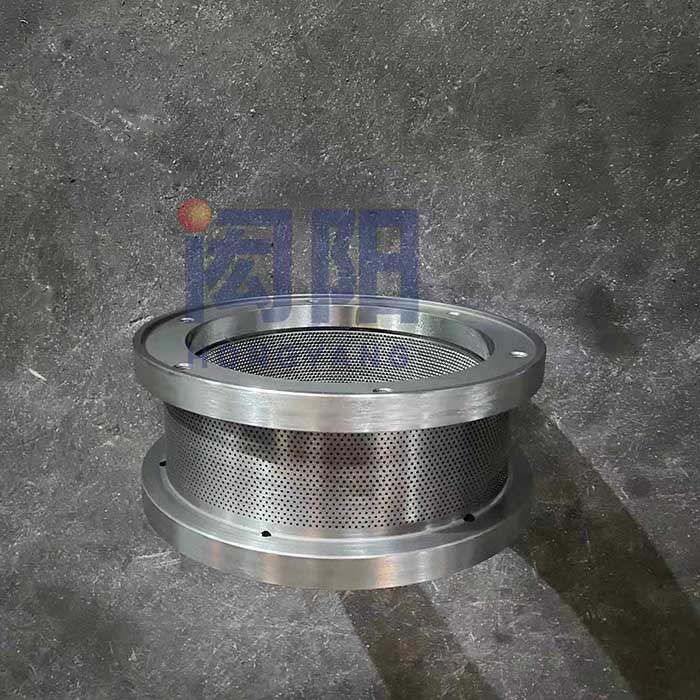

1. Xaiv qhov zoo tshaj plaws tawm ntawm qhov cub refining thiab degassed billets.

2. Cov pwm txais yuav cov phom tho txawv teb thiab ntau lub chaw nres tsheb laum, lub qhov pwm yog tsim nyob rau hauv ib lub sij hawm, qhov tiav yog siab, cov tsos ntawm cov khoom noj yog zoo nkauj, cov zis yog siab, cov khoom yog tawm smoothly, thiab cov khoom yog tsim zoo.

3. Cov pwm siv cov txheej txheem kev kho mob sib xyaw ua ke ntawm American lub tshuab nqus tsev vacuum thiab txuas ntxiv quenching rauv, uas muaj qhov sib txawv quenching, zoo nto tiav thiab siab hardness, kom ntseeg tau ob zaug ntawm kev pab cuam lub neej.

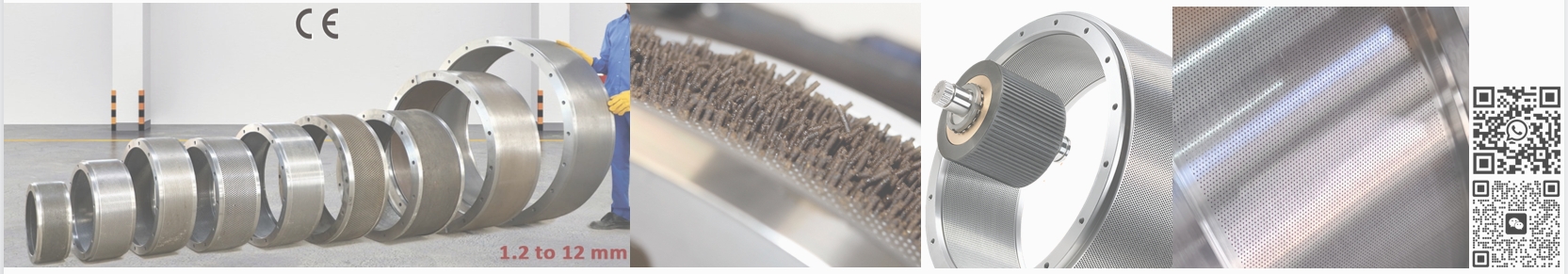

Khoom Qhia

Txij li xyoo 2006, peb lub tuam txhab tau cog lus rau kev tsim cov chaw tsim tshuaj lom neeg rau lub nplhaib tuag.Cov tuag tsim yog tsim rau nqaij qaib, os, ntses, cws, ntoo chips, composite cov ntaub ntawv, thiab lwm yam, thiab tam sim no nyob rau hauv ib tug paub tab theem ntawm technology.Peb lub tuam txhab txais CNC tsib-axis log pwm pwm rab phom laum tshuab, plaub-lub taub hau rab phom xyaum, CNC nplhaib pwm chamfering tshuab.

Cov qauv yooj yim ntawm lub nplhaib tuag tsim los ntawm lub tuam txhab yog: 200-600;txhua hom kev tuag los ntawm Zhengchang, Muyang, Shende thiab CPM tuaj yeem xaj.

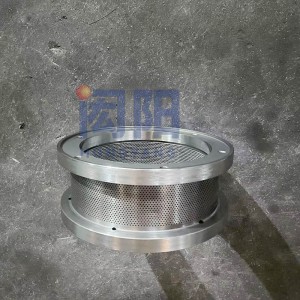

Kev daws teeb meem thaiv

Yog tias lub nplhaib tuag raug thaiv thaum lub sij hawm pellet ntau lawm, nws yuav tsum tau muab tshem tawm ntawm lub tshuab thiab ntxuav.

1. Txoj kev uas feem ntau yog siv lub laum hluav taws xob kom tau cov khoom noj uas txhaws hauv qhov tuag.

2. Yog hais tias txoj kab uas hla ntawm lub nplhaib thaiv tuag yog tsawg dua 2.5 hli, lub nplhaib tuag tuaj yeem muab tso rau hauv dej thiab cua sov.Cov khoom nyob rau hauv lub pwm qhov yuav maj mam nthuav thiab protrude tawm ntawm pwm qhov los ntawm lub sij hawm ntev ntawm boiling, kom cov khoom nyob rau hauv lub qhov yuav xoob.Tom qab 1 lossis 2 hnub ntawm kev ua noj, khawb tawm cov khoom tawm, tom qab ntawd muab lub nplhaib tuag rau ntawm granulator rau kev sib tsoo, thiab nias tawm cov khoom seem hauv lub qhov.

3. Me me aperture nplhaib tuag clogging kuj tseem siv tau los ua noj cov tuag nrog cov roj kub, kom cov khoom nyob rau hauv lub qhov tuag ntawm high-temperature coke, ua me me, thiab tom qab ntawd tshem tawm.Kev xyaum tshwj xeeb: ua ib lub tais hlau loj dua lub nplhaib tuag, muab lub nplhaib tuag rau hauv nws, ntxiv No.15 roj thiab ua rau nws poob rau saum npoo tuag;sov cov roj li 6-8 teev, kom txog thaum cov roj tsis tshua muaj npuas.