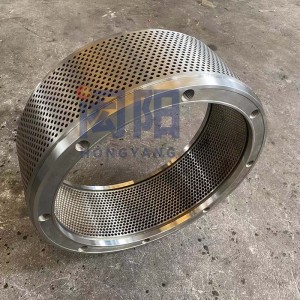

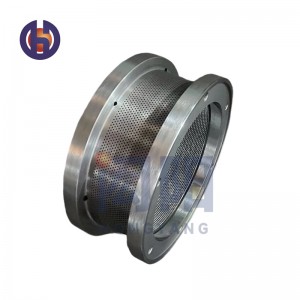

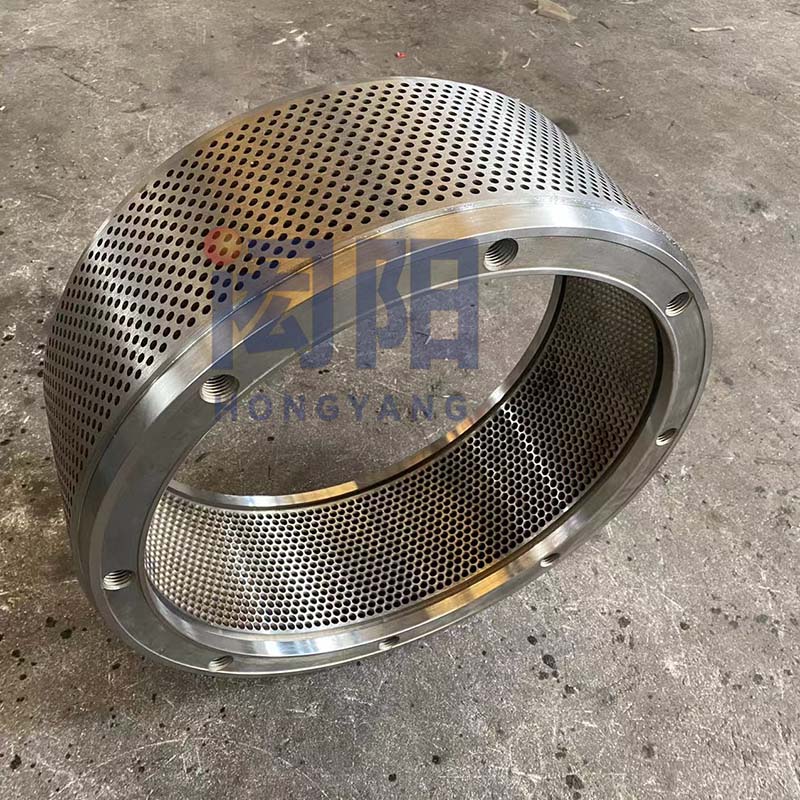

Pellet Zeb Tuag PTN580 Nplhaib Tuag

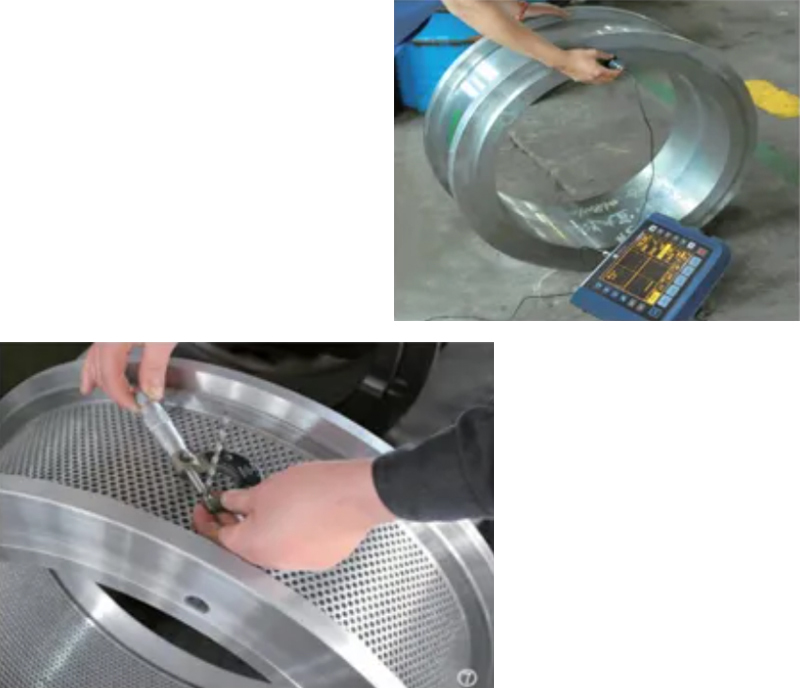

Kev tshuaj xyuas cov khoom

1. 100% ultrasonic flaw nrhiav, nruj me ntsis tswj qhov zoo ntawm qhov chaw dawb paug;

2. 100% hardness testing, tswj lub tempering zoo ntawm lub nplhaib tuag forgings, kev txhim kho qhov sib ntxiv, refining lub grain qauv, thiab xyuas kom meej qhov zoo ntawm pellets.

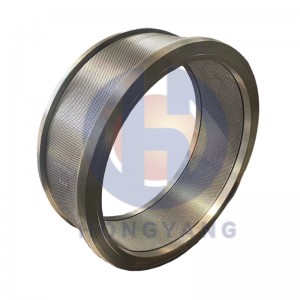

3. Txheeb xyuas qhov kab ntawm lub nplhaib tuag. Txoj kab uas hla ntawm lub nplhaib tuag yuav tsum muaj tseeb thiab zoo ib yam los xyuas kom meej qhov sib xws ntawm cov khoom tsim.

4. Tshawb xyuas lub nplhaib tuag qhov. Xyuas kom lub smoothness ntawm lub nplhaib tuag qhov.

5. Txheeb xyuas qhov chaw tiav: qhov kawg ntawm lub nplhaib tuag yuav tsum du thiab tsis muaj qhov tsis xws luag. Txhua qhov chaw ntxhib lossis cov npoo ntse tuaj yeem ua rau cov khoom siv biomass puas tsuaj thiab cuam tshuam rau pellet zoo.

Los ntawm kev tshuaj xyuas qhov zoo ntawm koj lub nplhaib pellet zeb tuag los ntawm cov khoom siv raw mus rau cov khoom tiav, peb tuaj yeem xyuas kom meej tias koj tuaj yeem tsim cov pellets zoo nrog peb cov khoom uas yuav ua tau raws li koj cov kev xav tau tshwj xeeb.

Khoom Qhia

Txog Peb

Txij li xyoo 2006, peb lub tuam txhab tau mob siab rau kev tsim cov nplhaib pwm ua cov chaw tsim khoom. Cov pwm tsim yog tsim rau nqaij qaib, os, ntses, cws, ntoo chips, thiab cov khoom sib xyaw. Peb lub tuam txhab tau nruab nrog CNC tsib-axis log pwm pwm phom drilling tshuab, plaub-lub taub hau rab phom drilling tshuab, thiab CNC nplhaib pwm chamfering tshuab.

Peb cov khoom tau yeej lub koob npe nrov hauv txhua lub tebchaws uas muaj feem xyuam. Peb cov kws tshaj lij R & D tsim nyog yuav nyob ntawd los muab kev pabcuam rau koj thiab peb yuav ua peb qhov zoo tshaj plaws kom tau raws li koj cov kev xav tau. Yog li ntawd, thov koj xav tiv tauj peb rau kev sab laj. Peb yuav twv yuav raug hu muab qhov zoo tshaj plaws hais lus thiab kev pab cuam tom qab muag.