Particle hardness yog ib qho ntawm cov ntsuas zoo uas txhua lub tuam txhab pub khoom noj tau zoo heev rau. Nyob rau hauv cov tsiaj nyeg thiab nqaij qaib pub, siab tawv yuav ua rau tsis zoo palatability, txo cov khoom noj, thiab tseem ua rau lub qhov ncauj rwj hauv cov npua suckling. Txawm li cas los xij, yog tias qhov hardness tsawg, cov hmoov cov ntsiab lus yuav nce ntxiv. Qhov qis hardness ntawm loj, tshwj xeeb tshaj yog nruab nrab thiab loj npua thiab nruab nrab duck pellet poultry pub yuav ua rau cov khoom tsis zoo xws li kev pub zaub mov. Yuav ua li cas kom ntseeg tau tias cov khoom noj hardness ua tau raws li cov qauv zoo? Lub hardness ntawm cov khoom pub, ntxiv rau kev hloov kho ntawm cov qauv pub, kev tsim cov khoom noj Cov txheej txheem kev ua haujlwm muaj qhov cuam tshuam tseem ceeb rau qhov hardness ntawm pellet pub.

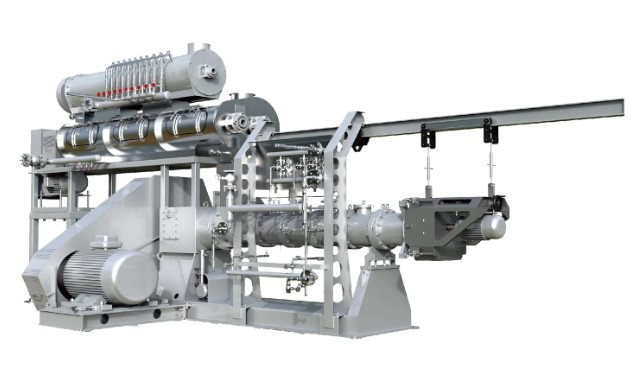

1. Kev cuam tshuam ntawm kev sib tsoo ntawm particle hardness.

Qhov tseem ceeb uas ua lub luag haujlwm txiav txim siab hauv cov txheej txheem sib tsoo yog qhov sib tsoo me me ntawm cov ntaub ntawv raw: Feem ntau hais lus, qhov zoo dua qhov sib tsoo me me ntawm cov khoom siv raw, qhov yooj yim dua rau cov hmoov txhuv nplej siab rau gelatinize thaum lub sij hawm txias, thiab qhov muaj zog ntawm kev sib koom ua ke hauv cov pellets. Qhov nyuaj dua nws yog tawg, qhov hardness ntau dua. Hauv kev tsim khoom tiag tiag, qhov kev xav tau ntawm crushing particle loj yuav tsum tau kho kom haum raws li kev ua tau zoo ntawm cov tsiaj sib txawv thiab qhov loj ntawm lub nplhaib tuag aperture.

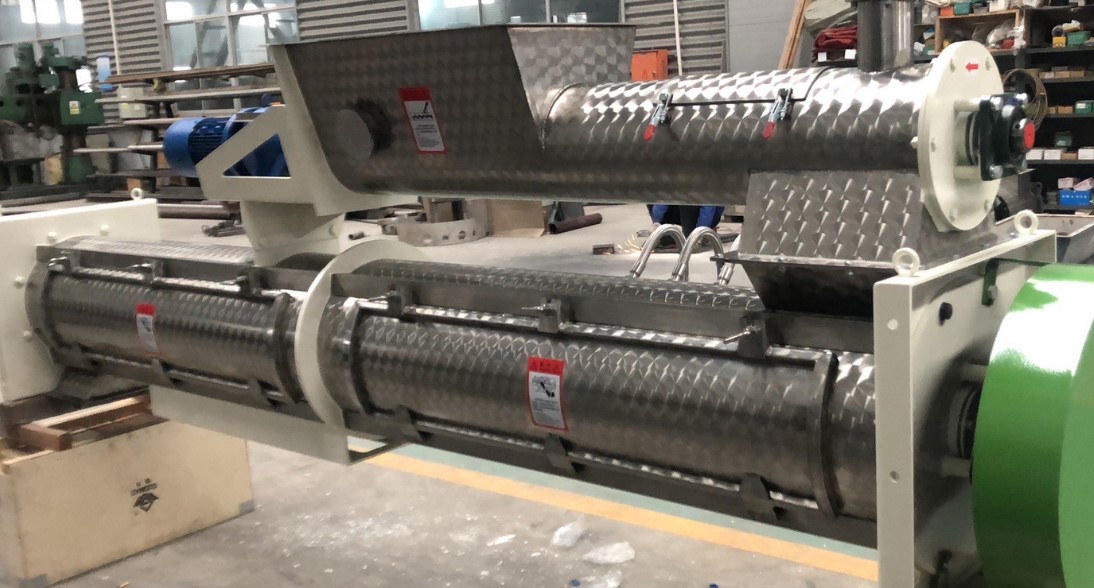

2. Kev cuam tshuam ntawm puffing txheej txheem ntawm particle hardness

Los ntawm puffing kev kho mob ntawm raw cov ntaub ntawv, co toxins nyob rau hauv cov ntaub ntawv raw tuaj yeem raug tshem tawm, cov kab mob tuaj yeem tua tau, cov khoom tsis zoo tuaj yeem raug tshem tawm, cov proteins hauv cov khoom siv raw tuaj yeem raug denatured, thiab cov hmoov txhuv nplej siab tuaj yeem ua tiav gelatinized. Tam sim no, puffed raw cov ntaub ntawv yog tsuas yog siv nyob rau hauv zus tau tej cov high-qib suckling npua pub thiab tshwj xeeb cov khoom noj khoom haus dej. Rau cov khoom siv dej tshwj xeeb, tom qab cov khoom siv raw yog puffed, qib ntawm cov hmoov txhuv nplej siab gelatinization nce thiab cov tawv nqaij ntawm cov khoom tsim kuj nce, uas yog qhov zoo rau kev txhim kho kev ruaj ntseg ntawm cov khoom hauv dej. Rau kev pub npua noj, cov khoom yuav tsum yog crispy thiab tsis tawv heev, uas yog qhov zoo rau kev noj cov npua suckling. Txawm li cas los xij, vim tias qib siab ntawm cov hmoov txhuv nplej siab gelatinization hauv puffed suckling npua pellets, lub hardness ntawm pub pellets kuj tseem loj.

3. Ntxiv qhov cuam tshuam ntawm cov txheej txheem kev txhaj tshuaj ntawm cov khoom noj hardness.

Kev sib xyaw ntawm cov khoom siv raw tuaj yeem txhim kho qhov sib xws ntawm ntau yam khoom me me, uas yog qhov zoo rau kev ua kom cov khoom tawv tawv zoo ib yam thiab txhim kho cov khoom zoo. Hauv kev tsim cov khoom noj pellet nyuaj, ntxiv 1% mus rau 2% noo noo nyob rau hauv lub tov khoom yuav pab txhim kho kev ruaj ntseg thiab hardness ntawm pellet pub. Txawm li cas los xij, qhov nce hauv cov dej noo ua rau muaj qhov tsis zoo rau qhov ziab thiab txias ntawm cov khoom. Nws kuj tsis haum rau kev khaws cov khoom. Hauv kev tsim cov pellet ntub dej, tuaj yeem ntxiv rau 20% mus rau 30% noo noo. Nws yog ib qho yooj yim los ntxiv txog 10% noo noo thaum lub sij hawm sib tov dua thaum lub sij hawm txias txheej txheem. Cov granules tsim los ntawm cov ntaub ntawv uas muaj dej-nqus dej tsis tshua muaj hardness, yog ntub thiab mos, thiab muaj palatability zoo. Hom ntub pellet pub no tuaj yeem siv rau hauv kev lag luam loj loj. Cov pellets ntub dej feem ntau nyuaj rau khaws cia thiab feem ntau yuav tsum tau noj tam sim tom qab tsim khoom. Ntxiv cov roj thaum lub sij hawm sib tov yog ib qho kev siv roj ntxiv hauv cov kev cob qhia pub khoom noj. Ntxiv 1% mus rau 2% ntawm cov roj muaj qhov cuam tshuam me ntsis ntawm kev txo cov tawv ntawm cov khoom, thaum ntxiv 3% mus rau 4% ntawm cov roj tuaj yeem txo qhov hardness ntawm cov khoom.

4. Cov nyhuv ntawm chav txias rau particle hardness.

Chav txias yog cov txheej txheem tseem ceeb hauv kev ua cov khoom noj pellet, thiab cov nyhuv txias ncaj qha cuam tshuam rau cov qauv sab hauv thiab cov tsos zoo ntawm cov pellets. Chav zoo thiab lub sij hawm txias yog ob yam tseem ceeb uas cuam tshuam rau qhov txias txias. Cov khoom zoo qhuav thiab saturated chav muaj peev xwm muab cua sov ntau ntxiv kom qhov kub thiab txias ntawm cov khoom thiab gelatinize cov hmoov txhuv nplej siab. Lub sijhawm txias dua, qhov siab dua ntawm cov hmoov txhuv nplej siab gelatinization. Qhov siab dua tus nqi, qhov denser particle qauv tom qab tsim, qhov zoo dua qhov ruaj khov, thiab ntau dua qhov hardness. Rau cov ntses pub, ob-txheej los yog ntau-txheej tsho feem ntau yog siv rau kev txias kom txias txias thiab txuas ntxiv lub sijhawm txias. Nws yog qhov tsim nyog rau kev txhim kho kev ruaj ntseg ntawm cov ntses noj cov khoom hauv dej, thiab cov tawv tawv ntawm cov khoom kuj nce ntxiv.

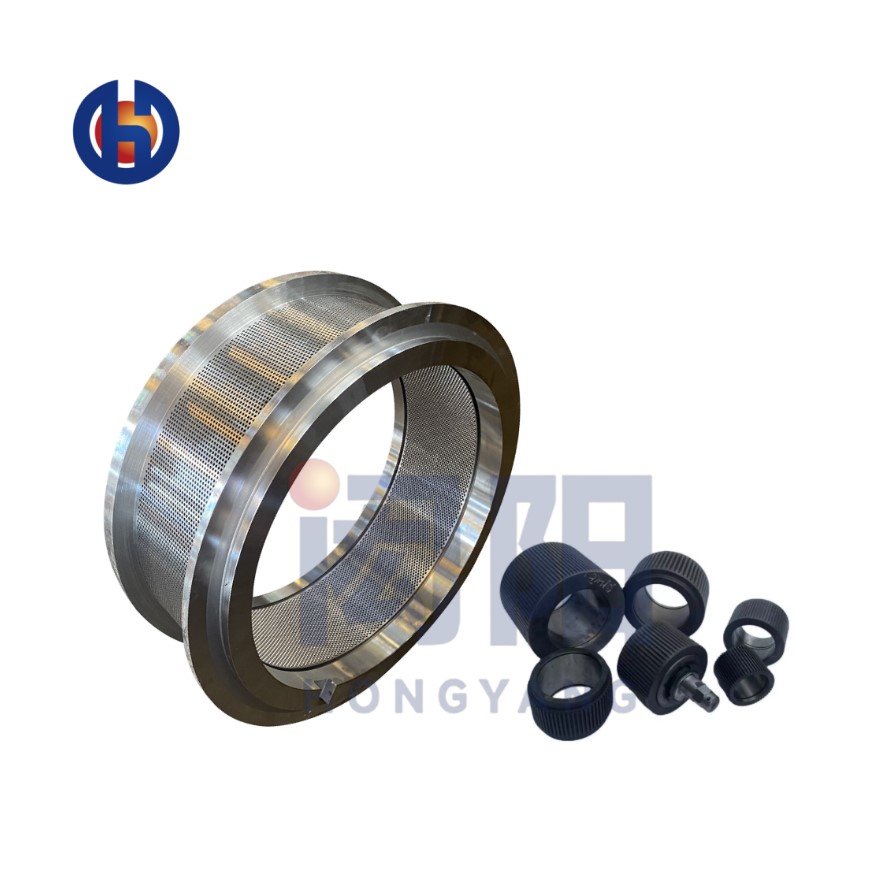

5. Lub zog ntawm lub nplhaib tuag ntawm particle hardness.

Technical parameters xws li aperture thiab compression piv ntawm lub nplhaib tuag ntawm feed pellet zeb cuam tshuam rau hardness ntawm pellets. Lub hardness ntawm cov pellets tsim los ntawm lub nplhaib tuag nrog tib lub aperture tab sis sib txawv compression ratios nce ho raws li qhov compression piv nce. Xaiv qhov tsim nyog compression piv nplhaib tuag tuaj yeem tsim cov khoom ntawm qhov tsim nyog hardness. Qhov ntev ntawm cov khoom muaj qhov cuam tshuam loj rau lub siab-kev muaj peev xwm ntawm cov khoom. Rau cov khoom ntawm tib txoj kab uas hla, yog tias cov khoom tsis muaj qhov tsis xws luag, qhov ntev ntawm qhov ntev, qhov hnyav dua qhov ntsuas. Kho qhov chaw ntawm lub tshuab txiav kom tswj tau qhov ntev ntawm qhov tsim nyog tuaj yeem ua kom cov tawv tawv ntawm cov khoom sib xws. Lub particle inch thiab cross-sectional shape kuj muaj qee yam cuam tshuam rau particle hardness. Tsis tas li ntawd, cov khoom ntawm lub nplhaib tuag kuj muaj qee yam cuam tshuam rau cov tsos zoo thiab hardness ntawm cov pellets. Muaj qhov sib txawv ntawm qhov sib txawv ntawm cov pellet pub ua los ntawm cov hlau zoo tib yam lub nplhaib tuag thiab stainless hlau nplhaib tuag.

6. Kev cuam tshuam ntawm cov txheej txheem tom qab txau ntawm particle hardness.

Txhawm rau txuas ntxiv lub sijhawm cia ntawm cov khoom noj khoom haus thiab txhim kho cov khoom zoo nyob rau hauv ib lub sijhawm, qhov tsim nyog kom qhuav thiab ua kom txias ntawm cov khoom noj yuav tsum tau ua. Hauv kev sim ntsuas qhov hardness ntawm cov khoom, los ntawm kev ntsuas qhov hardness ntawm cov khoom rau tib yam khoom ntau zaus nrog lub sijhawm txias sib txawv, nws tau pom tias cov khoom uas tsis tshua muaj hardness tsis cuam tshuam rau lub sijhawm txias, thaum cov khoom nrog cov hardness loj dua nrog lub sijhawm txias. Thaum lub sij hawm nce, particle hardness txo. Qhov no tej zaum yuav yog vim hais tias raws li cov dej nyob rau hauv cov hais yog ploj, lub brittleness ntawm cov khoom yuav nce, cuam tshuam cov particle hardness. Nyob rau tib lub sijhawm, tom qab cov khoom tau txias sai heev nrog cov huab cua loj thiab maj mam txias nrog cov huab cua me me, nws tau pom tias qhov nyuaj ntawm qhov qub tau qis dua qhov tom kawg, thiab cov kab nrib pleb ntawm cov khoom tau nce ntxiv. Nws tseem tsim nyog hais tias crushing loj cov khoom nyuaj rau hauv cov khoom me me tuaj yeem txo qhov hardness ntawm cov khoom.

Post lub sij hawm: Mar-14-2024