Hauv kev tsim cov khoom noj tiag tiag, vim muaj ntau yam, "cov khoom siv lub lauj kaub" tuaj yeem tsim ntawm lub nplhaib tuag thiab lub siab rau cov menyuam, ua rau muaj teeb meem xws li jamming, blockage, thiab slipping ntawm granulator.

Peb tau kos cov lus xaus hauv qab no los ntawm kev tsom xam cov tswv yim thiab kev paub ntawm qhov chaw teeb meem:

Peb tau kos cov lus xaus hauv qab no los ntawm kev tsom xam cov tswv yim thiab kev paub ntawm qhov chaw teeb meem:

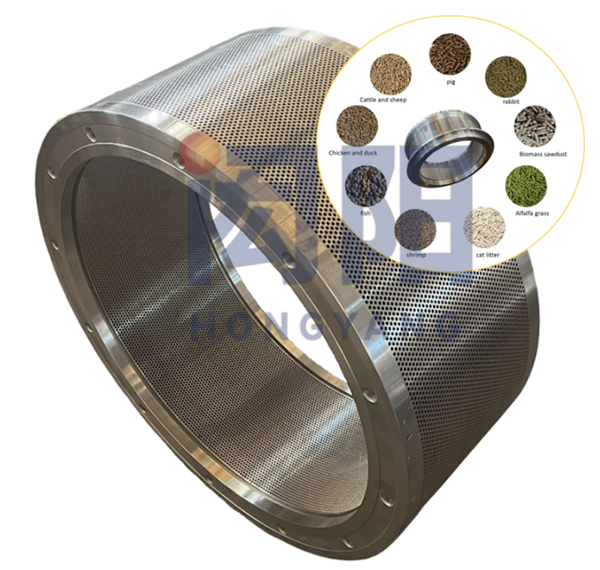

1 、 Cov khoom siv raw

Cov ntaub ntawv uas muaj cov hmoov txhuv nplej siab siab yog nquag ua rau cov gelatinization thiab muaj qee yam viscosity, uas yog qhov zoo rau molding; Rau cov ntaub ntawv uas muaj coarse fibers, ib tug ntau npaum li cas ntawm cov roj yuav tsum tau ntxiv kom txo tau kev sib txhuam thaum lub sij hawm granulation txheej txheem, uas yog zoo rau cov khoom kom dhau los ntawm lub nplhaib pwm thiab lub resulting granular khoom muaj ib tug du tsos.

2 、 Tsis raug tuag yob tshem tawm

Qhov sib txawv ntawm cov pwm chais yog loj heev, ua rau cov khoom txheej ntawm cov pwm rollers tuab heev thiab tsis sib npaug. Lub siab rau cov menyuam yaus ua rau plam vim qhov tsis sib xws, thiab cov khoom siv tsis tuaj yeem rub tawm, ua rau lub tshuab thaiv. Txhawm rau txo lub tshuab thaiv, kev saib xyuas yuav tsum tau them rau kev kho qhov sib txawv ntawm cov pwm chais thaum lub sij hawm tsim khoom, feem ntau yog 3-5 hli.

3 、 Qhov cuam tshuam ntawm chav ua haujlwm zoo

3 、 Qhov cuam tshuam ntawm chav ua haujlwm zoo

Cov xwm txheej zoo tshaj plaws rau cov txheej txheem granulation yog: cov dej noo tsim nyog ntawm cov khoom siv raw, chav ua haujlwm zoo, thiab lub sijhawm tempering txaus. Txhawm rau kom ntseeg tau qhov zoo ntawm cov khoom zoo thiab cov zis siab, ntxiv rau kev ua haujlwm ib txwm muaj ntawm ntau qhov sib kis ntawm cov granulator, qhov zoo ntawm cov khoom siv hluav taws xob qhuav nkag mus rau hauv granulator lub txias yuav tsum tau ua kom ntseeg tau.

Qhov tsis zoo ntawm chav ua rau muaj cov dej noo siab ntawm cov khoom thaum tawm hauv lub tshuab txias, uas tuaj yeem yooj yim ua rau txhaws ntawm lub qhov pwm thiab plam ntawm lub siab cov menyuam thaum lub sij hawm granulation txheej txheem, uas ua rau clogging ntawm lub tshuab. Tshwj xeeb manifested nyob rau hauv:

① Tsis txaus lub zog siab thiab cov dej noo siab tuaj yeem ua rau cov khoom nqus dej ntau dhau. Nyob rau tib lub sijhawm, thaum lub siab qis, qhov kub thiab txias thaum cov khoom tempered kuj qis, thiab cov hmoov txhuv nplej siab tsis tuaj yeem gelatinize zoo, ua rau cov nyhuv granulation tsis zoo;

② Lub zog siab tsis ruaj khov, hloov pauv ntawm qhov siab mus rau qis, thiab cov khoom zoo tsis ruaj khov, ua rau muaj kev hloov pauv loj hauv cov granulator tam sim no, cov khoom tsis sib xws nqhis dej, thiab yooj yim thaiv thaum lub sij hawm tsim khoom.

Txhawm rau txo tus naj npawb ntawm cov tshuab nres uas tshwm sim los ntawm qhov tsis zoo, cov neeg ua haujlwm pub khoom noj yuav tsum tau them sai sai rau cov dej noo ntawm cov khoom tom qab tempering txhua lub sijhawm. Txoj hauv kev yooj yim los txiav txim siab yog txhawm rau rub ib txhais tes ntawm cov khoom siv los ntawm lub tshuab txias thiab tuav nws hauv lub pob, thiab cia mus rau tsuas yog tawg.

4 、 Siv lub nplhaib tshiab tuag

4 、 Siv lub nplhaib tshiab tuag

Feem ntau hais lus, thaum lub nplhaib tshiab tuag yog thawj zaug siv, nws yuav tsum tau ua hauv av nrog cov ntaub ntawv oily, nrog rau qhov tsim nyog nce ntawm 30% ntawm cov xuab zeb emery, thiab hauv av rau li 20 feeb; Yog tias muaj ntau yam khoom siv hauv granulation chamber, thiab tam sim no txo qis piv rau kev sib tsoo, nws kuj tseem ruaj khov, thiab qhov hloov pauv me me. Lub sijhawm no, lub tshuab tuaj yeem nres thiab qhov xwm txheej granulation tuaj yeem kuaj xyuas. Cov granulation yog uniform thiab ncav cuag tshaj 90%. Nyob rau lub sijhawm no, siv cov ntaub ntawv oily los nias rau hauv thiab hloov cov khoom siv xuab zeb los tiv thaiv kev thaiv tom ntej.

5 、 Yuav ua li cas tshem tawm qhov thaiv

5 、 Yuav ua li cas tshem tawm qhov thaiv

Yog hais tias lub nplhaib pwm raug thaiv thaum lub sij hawm tsim khoom, ntau lub tuam txhab pub khoom siv hluav taws xob laum los ntawm cov khoom siv, uas yuav ua rau lub qhov smoothness ntawm pwm thiab ua rau muaj kev puas tsuaj rau qhov zoo nkauj ntawm cov khoom.

Ib txoj hauv kev zoo tshaj plaws yog kom npau npau lub nplhaib pwm hauv cov roj, uas yog siv lub lauj kaub hlau, muab cov roj cav pov tseg rau hauv nws, muab cov pwm thaiv hauv nws, thiab tom qab ntawd kub thiab ua kom sov hauv qab kom txog thaum lub suab tawg, thiab tom qab ntawd tshem tawm. Tom qab txias, lub installation tiav, thiab lub granulator rov pib dua raws li kev khiav hauj lwm specifications. Cov ntaub ntawv thaiv lub nplhaib pwm tuaj yeem raug ntxuav sai sai yam tsis muaj kev puas tsuaj rau cov khoom tiav.

Post lub sij hawm: Lub Xya hli ntuj-19-2023