Hauv kev ua cov khoom noj pellet, siab pulverization tus nqi tsis tsuas yog cuam tshuam rau cov khoom noj zoo, tab sis kuj nce nqi ua. Los ntawm kev soj ntsuam kuaj, pulverization tus nqi ntawm pub tuaj yeem pom pom, tab sis nws tsis tuaj yeem nkag siab qhov laj thawj ntawm pulverization hauv txhua txoj kev. Yog li ntawd, nws raug pom zoo tias cov kws tsim khoom noj khoom haus ntxiv dag zog rau kev saib xyuas zoo ntawm txhua ntu thiab siv kev tiv thaiv thiab tswj kev ntsuas ib txhij.

1, Pub mis mis

Vim muaj qhov sib txawv ntawm cov khoom noj khoom haus, kev ua haujlwm nyuaj yuav txawv. Piv txwv li, pub nrog cov protein tsawg thiab cov roj cov ntsiab lus yooj yim dua rau granulate thiab txheej txheem, thaum pub nrog cov ntsiab lus siab tsis tshua tsim, ua rau cov khoom xoob thiab cov pulverization ntau dua. Yog li thaum txiav txim siab pub granulation comprehensively, cov mis yog qhov yuav tsum tau ua ua ntej, thiab qhov nyuaj ntawm kev ua haujlwm yuav tsum tau txiav txim siab ntau npaum li qhov ua tau los xyuas kom meej tag nrho cov khoom zoo.

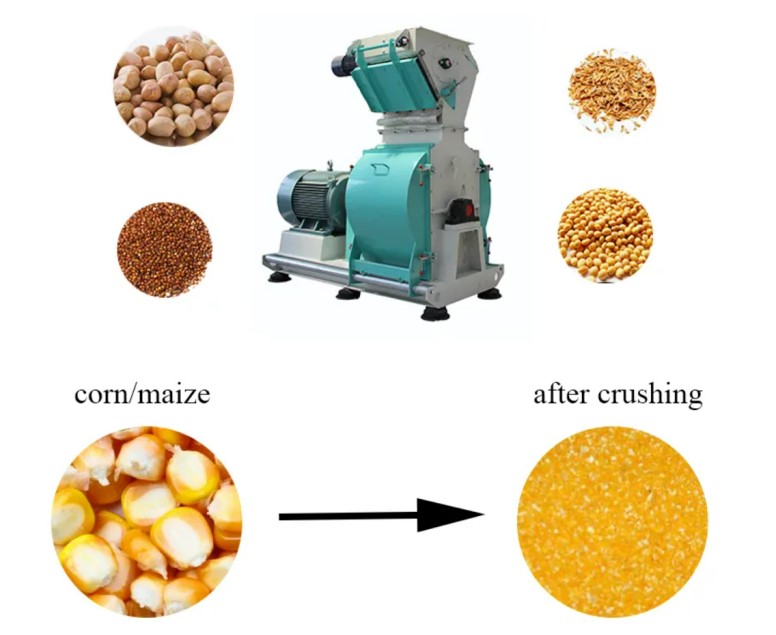

2. Crushing seem

Qhov me me me ntawm cov khoom siv raw crushing, qhov loj ntawm qhov chaw ntawm cov khoom, qhov zoo dua qhov adhesion thaum lub sij hawm granulation, thiab qhov zoo dua ntawm granulation. Tab sis yog tias nws tsawg dhau, nws yuav ncaj qha rhuav tshem cov as-ham. Xaiv cov khoom sib txawv crushing particle loj raws li cov kev xav tau zoo thiab kev tswj tus nqi yog qhov tseem ceeb. Tswv yim: Ua ntej pelletizing cov tsiaj nyeg thiab nqaij qaib pub, qhov loj me ntawm cov hmoov yuav tsum muaj tsawg kawg yog 16 mesh, thiab ua ntej pelletizing dej pub, qhov loj ntawm cov hmoov yuav tsum yog tsawg kawg yog 40 mesh.

3.Granulation seem

Cov ntsiab lus dej tsawg los yog siab, qhov kub thiab txias tsis tshua muaj kev cuam tshuam rau granulation zoo, tshwj xeeb tshaj yog tias lawv qis dhau, lawv yuav ua rau cov granulation ntawm cov khoom noj tsis nruj, thiab cov particle puas thiab pulverization tus nqi yuav nce. Tswv yim: Tswj cov dej ntsiab lus thaum tempering ntawm 15-17%. Kub: 70-90 ℃ (lub inlet chav yuav tsum depressurized rau 220-500kpa, thiab inlet chav kub yuav tsum tau tswj nyob ib ncig ntawm 115-125 ℃).

4. Cua txias seem

Kev tsis sib xws ntawm cov ntaub ntawv los yog lub sijhawm txias ntau dhau tuaj yeem ua rau cov khoom tawg, ua rau cov khoom noj tsis zoo thiab tawg yooj yim, yog li ua rau pulverization tus nqi. Yog li ntawd, nws yog ib qho tsim nyog los xaiv cov khoom siv cua txias kom ntseeg tau thiab sib npaug ntawm cov khoom.

5 、 Kev tshuaj xyuas ntu

Cov thickness ntau dhau los yog tsis sib npaug ntawm cov txheej txheem ntawm cov khoom siv tshuaj ntsuam xyuas tuaj yeem ua rau tsis tiav kev tshuaj ntsuam, uas ua rau muaj kev nce hauv cov ntsiab lus hmoov hauv cov khoom tiav. Kev tso tawm sai sai ntawm lub tshuab txias tuaj yeem yooj yim ua rau cov tuab tuab ntawm cov txheej txheej txheej, thiab yuav tsum tau them nyiaj rau kev tiv thaiv.

6, Ntim seem

Cov txheej txheem ntim khoom tiav yuav tsum tau ua nyob rau hauv cov txheej txheem kev tsim khoom tas mus li, nrog rau cov khoom tiav warehouse khaws cia tsawg kawg yog 1/3 ntawm cov khoom tiav ua ntej pib ntim, txhawm rau kom tsis txhob muaj qhov nce ntawm cov hmoov hauv cov khoom tiav los ntawm cov khoom noj poob los ntawm qhov chaw siab.

Post lub sij hawm: Oct-24-2023