Thaum lub sij hawm granulation txheej txheem ntawm lub tshuab pub pellet, muaj ib tug neeg pub pellets los yog ib tug neeg noj pellets nrog txawv xim, feem ntau hu ua "paj pub". Qhov teeb meem no yog tshwm sim nyob rau hauv zus tau tej cov dej pub, feem ntau manifested raws li cov xim ntawm ib tug neeg hais extruded los ntawm lub nplhaib tuag yog tsaus los yog sib zog dua lwm yam hais, los yog cov xim nto ntawm tus neeg hais tsis sib xws, yog li cuam tshuam cov tsos zoo ntawm tag nrho cov khoom noj.

Cov laj thawj tseem ceeb rau qhov tshwm sim no yog raws li hauv qab no:

a)Qhov sib xyaw ntawm cov khoom noj khoom haus yog qhov nyuaj heev, nrog ntau hom khoom siv raw, sib xyaw tsis sib xws, thiab cov ntsiab lus tsis sib xws ntawm cov hmoov ua ntej ua cov khoom noj.

b)Cov dej noo ntawm cov ntaub ntawv raw siv rau granulation yog inconsistent. Nyob rau hauv cov txheej txheem ntawm cov khoom noj hauv dej, feem ntau yuav tsum tau ntxiv cov dej me me rau hauv cov khoom sib tov txhawm rau txhawm rau txhawm rau txhawm rau poob dej hauv cov khoom siv raw tom qab ultrafine crushing. Tom qab sib tov, nws yog ces xa mus rau lub txias rau tempering. Qee lub tuam txhab pub khoom siv cov txheej txheem yooj yim dhau los ua cov khoom noj - muab cov ntaub ntawv xav tau rau cov mis ncaj qha rau hauv lub tov khoom thiab ntxiv dej txaus, es tsis txhob ua cov txheej txheem kom ntxaws thiab qeeb ntxiv raws li kev xav tau. Yog li ntawd, lawv pom tias nws nyuaj los xyuas kom meej qhov sib npaug ntawm cov khoom xyaw pub rau cov dej solubility. Thaum peb siv cov khoom xyaw sib xyaw no rau kev kho cua txias, peb yuav pom tias vim qhov ua tau zoo ntawm cov cua txias, cov dej noo tsis tuaj yeem tawg sai sai. Yog li ntawd, kev loj hlob ntawm cov txheej txheem pub khoom noj nyob rau hauv chav ua haujlwm sib txawv ntawm ntau qhov sib txawv, thiab xim hierarchy tom qab granulation ua tsis meej txaus.

c)Muaj cov khoom siv rov ua dua tshiab nrog cov granulation dua nyob rau hauv granulation rau hauv. Cov khoom siv granular tom qab granulation tsuas yog hloov mus rau hauv cov khoom tiav tom qab txias thiab tshuaj ntsuam. Cov tshuaj ntsuam xyuas cov hmoov zoo los yog cov khoom me me feem ntau nkag mus rau cov txheej txheem ntau lawm rau re granulation, feem ntau yog nyob rau hauv ib tug tov khoom los yog tos granulation silo. Vim lub fact tias cov khoom siv rov qab no yog re conditioned thiab granulated, yog hais tias nws yog tov unevenly nrog rau lwm yam auxiliary cov ntaub ntawv los yog tov nrog rov qab tshuab me me particle cov ntaub ntawv tom qab txias, tej zaum nws yuav tej zaum yuav tsim "paj khoom" rau tej yam zaub mov.

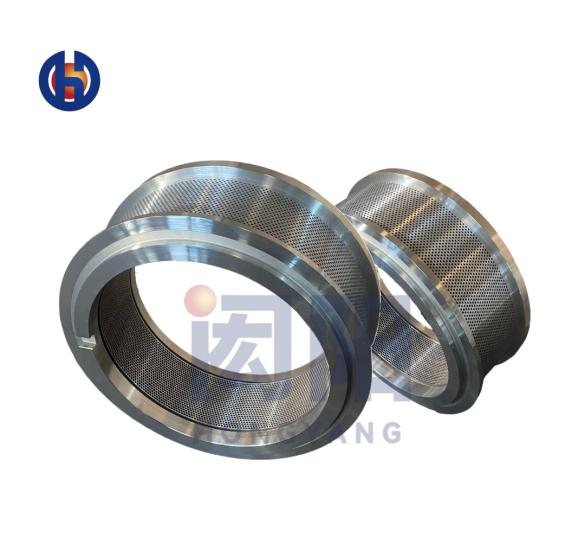

d)Lub smoothness ntawm lub puab phab ntsa ntawm lub nplhaib tuag aperture yog inconsistent. Vim qhov tsis sib xws ntawm qhov kawg ntawm qhov tuag, qhov tsis kam thiab extrusion siab uas cov khoom ntsib thaum extrusion txawv, ua rau cov xim tsis sib xws. Tsis tas li ntawd, qee lub nplhaib tuag muaj burrs ntawm lub qhov me me ntawm phab ntsa, uas tuaj yeem khawb qhov saum npoo ntawm cov khoom thaum lub sij hawm extrusion, uas ua rau cov xim sib txawv rau ib tus neeg.

Txoj kev txhim kho rau plaub qhov laj thawj ntawm kev tsim "paj ntaub ntawv" uas tau teev tseg saum toj no yog qhov tseeb heev, feem ntau tswj kev sib xyaw ua ke ntawm txhua qhov sib xyaw hauv cov qauv thiab qhov sib xyaw ua ke ntawm cov dej ntxiv; Txhim kho qhov quenching thiab tempering kev ua tau zoo tuaj yeem txo cov xim hloov; Tswj cov khoom siv tshuab rov qab. Rau cov qauv uas nquag tsim "paj khoom", sim tsis txhob ncaj qha granulate cov khoom siv rov qab tshuab. Cov khoom siv rov qab tshuab yuav tsum tau tov nrog cov khoom siv raw thiab rov crushed; Siv lub nplhaib tuag zoo los tswj qhov du ntawm qhov tuag qhov, thiab yog tias tsim nyog, zom lub nplhaib tuag qhov ua ntej siv.

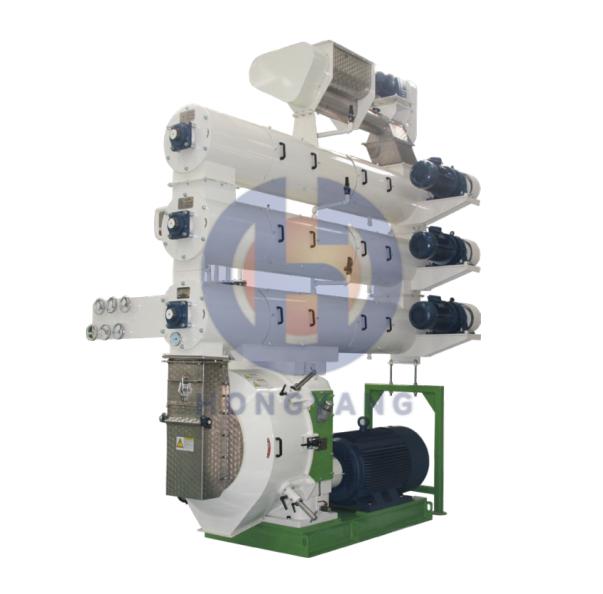

Nws raug nquahu kom teeb tsa ob txheej txheej dual axis sib txawv txias thiab ob txheej txuas ntxiv lub tsho txias, nrog lub sijhawm quenching txog li 60-120 vib nas this thiab quenching kub ntawm tshaj 100 ℃. Lub quenching yog uniform thiab kev ua tau zoo heev. Kev siv ntau lub ntsiab lus cua kom tau txais txiaj ntsig zoo heev ua rau thaj tsam ntu ntu ntawm cov khoom siv thiab chav dej, yog li txhim kho qhov loj hlob ntawm cov khoom thiab txhim kho cov nyhuv quenching thiab tempering; Cov cuab yeej digital vaj huam sib luag thiab ntsuas qhov ntsuas kub tuaj yeem tso saib qhov ntsuas kub ntawm qhov txias, ua kom yooj yim rau cov neeg siv tswj txhua lub sijhawm.

Kev Pabcuam Tiv Thaiv Cov Ntaub Ntawv:

Whatsapp: +8618912316448

E-mail:hongyangringdie@outlook.com

Post lub sij hawm: Lub Xya hli ntuj-26-2023